For seasoned seamstresses and designers, working with nylon spandex tricot offers a thrilling opportunity to create high-performance, aesthetically striking garments. This guide delves into the expert techniques needed to handle both plain and foil-enhanced nylon spandex tricot, ensuring your projects exhibit the highest level of craftsmanship.

Essential Tools and Setup

- Precision Cutting Tools: A rotary cutter paired with a high-quality cutting mat is indispensable for achieving precise, clean edges. For intricate designs, a pair of sharp fabric scissors can provide additional control.

- Microtex or Ballpoint Needles: While ballpoint needles are a staple for stretch fabrics, microtex needles can also be effective for finer, more detailed stitching on nylon spandex tricot.

- Sewing Machine and Serge: A high-end sewing machine with stretch stitch capabilities and a serge for seamless finishes are critical for professional results.

- Superior Pins and Clips: Use fine, sharp pins or fabric clips to minimize potential damage and maintain fabric integrity.

Preparing and Stabilizing the Fabric

- Advanced Fabric Prep: Pre-wash your fabric using a mild detergent and cold water to eliminate any finishing chemicals. This step is crucial for ensuring fabric behavior during cutting and sewing.

- Tissue Paper Technique: For particularly slippery or delicate sections, sandwiching the fabric between layers of tissue paper can stabilize it during cutting and sewing.

- Strategic Ironing: If necessary, use a tailor's ham for precision ironing around curves and avoid direct heat on foil areas. Always use a pressing cloth and the lowest possible heat setting.

Cutting Precision

- Rotary Cutter Mastery: Employ a rotary cutter for smooth, continuous cuts, especially along curves and intricate lines. Always ensure your blade is sharp to prevent snagging.

- Grainline and Stretch Considerations: Align pattern pieces meticulously with the fabric’s grainline to optimize stretch and durability. Consider the direction of the greatest stretch for functional garments.

- Clipping vs. Pinning: For foil fabrics, prefer using fabric clips to avoid leaving permanent marks. When pinning is necessary, use ultra-fine pins and place them within seam allowances.

Advanced Sewing Techniques

- Optimized Machine Settings: Utilize a stretch stitch or narrow zigzag stitch for seams. Adjust the stitch length and tension for each project, and always test on scrap fabric to fine-tune settings.

- Seam Stabilization: Incorporate clear elastic or stay tape within seams to prevent stretching and distortion, especially in areas subject to significant stress like necklines and armholes.

- Perfecting Hems: Use a twin needle for a refined hem finish that maintains stretch. Consider using a woolly nylon thread in the bobbin for added elasticity and softness.

- Serger Utilization: For an immaculate edge finish, a serger can be used to trim and enclose seams simultaneously. Adjust the differential feed to handle the stretch of the fabric without waviness.

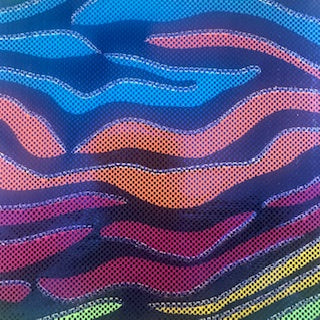

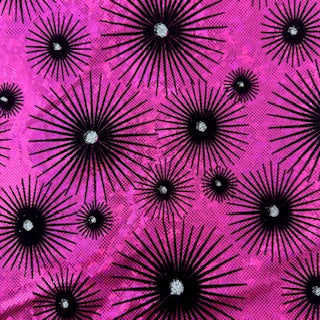

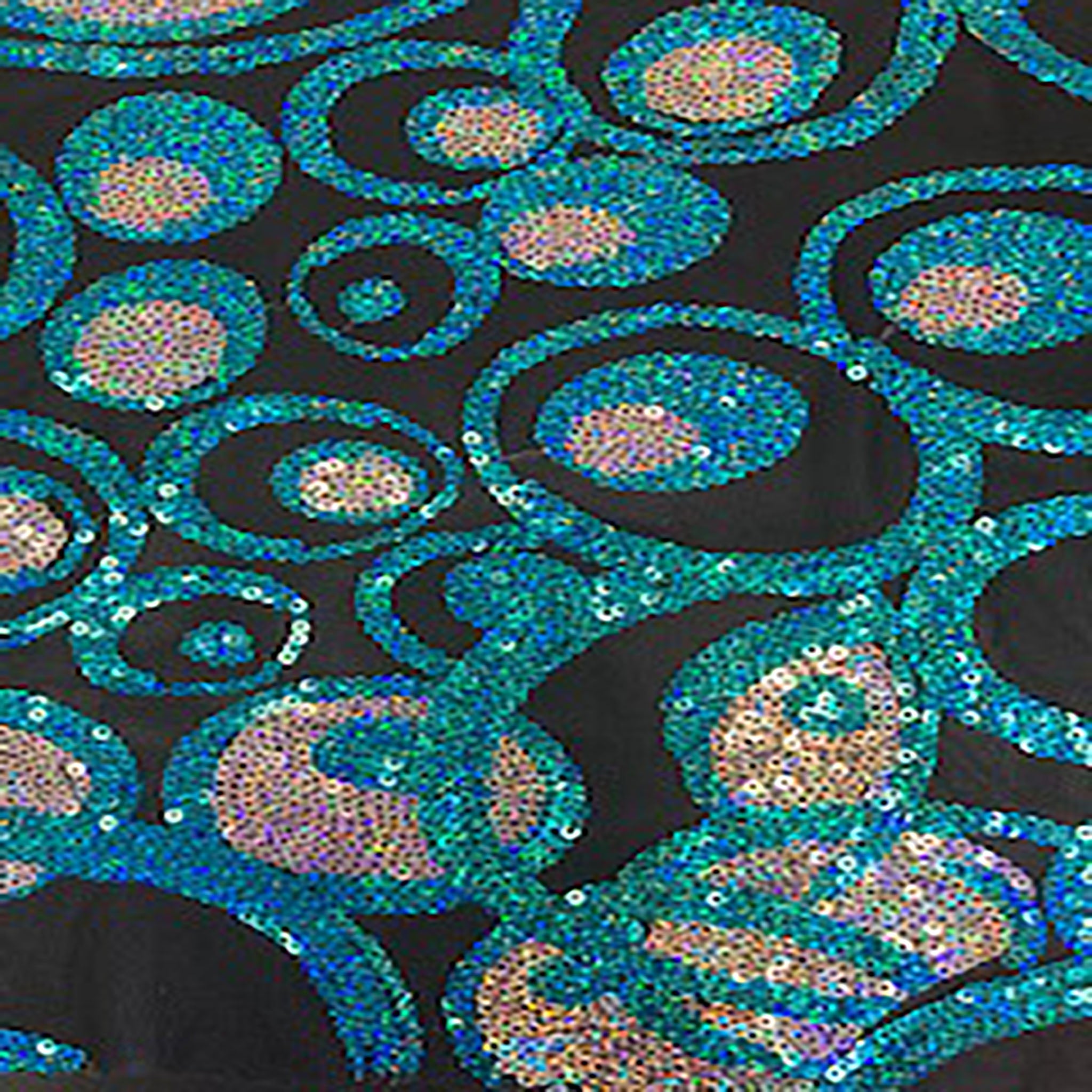

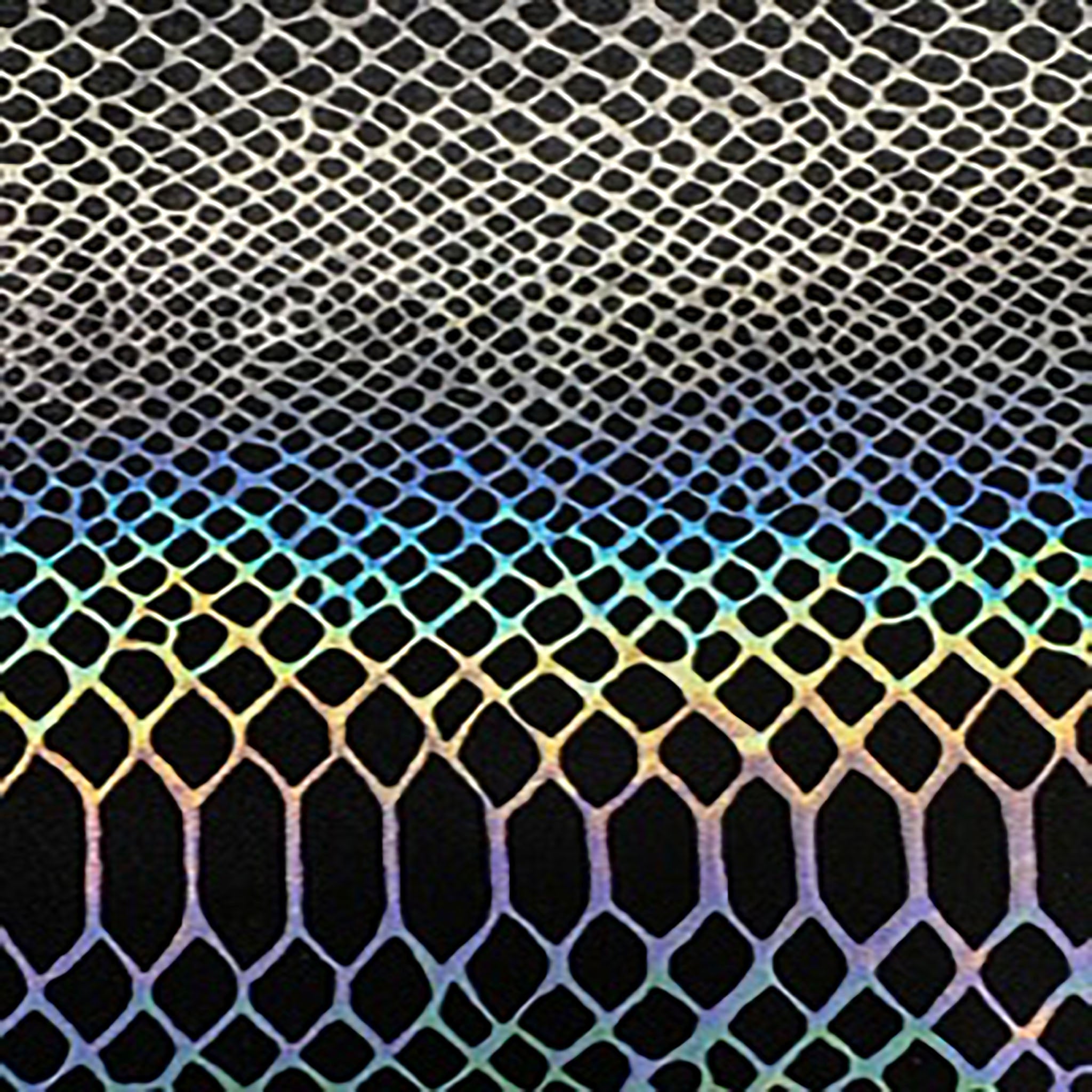

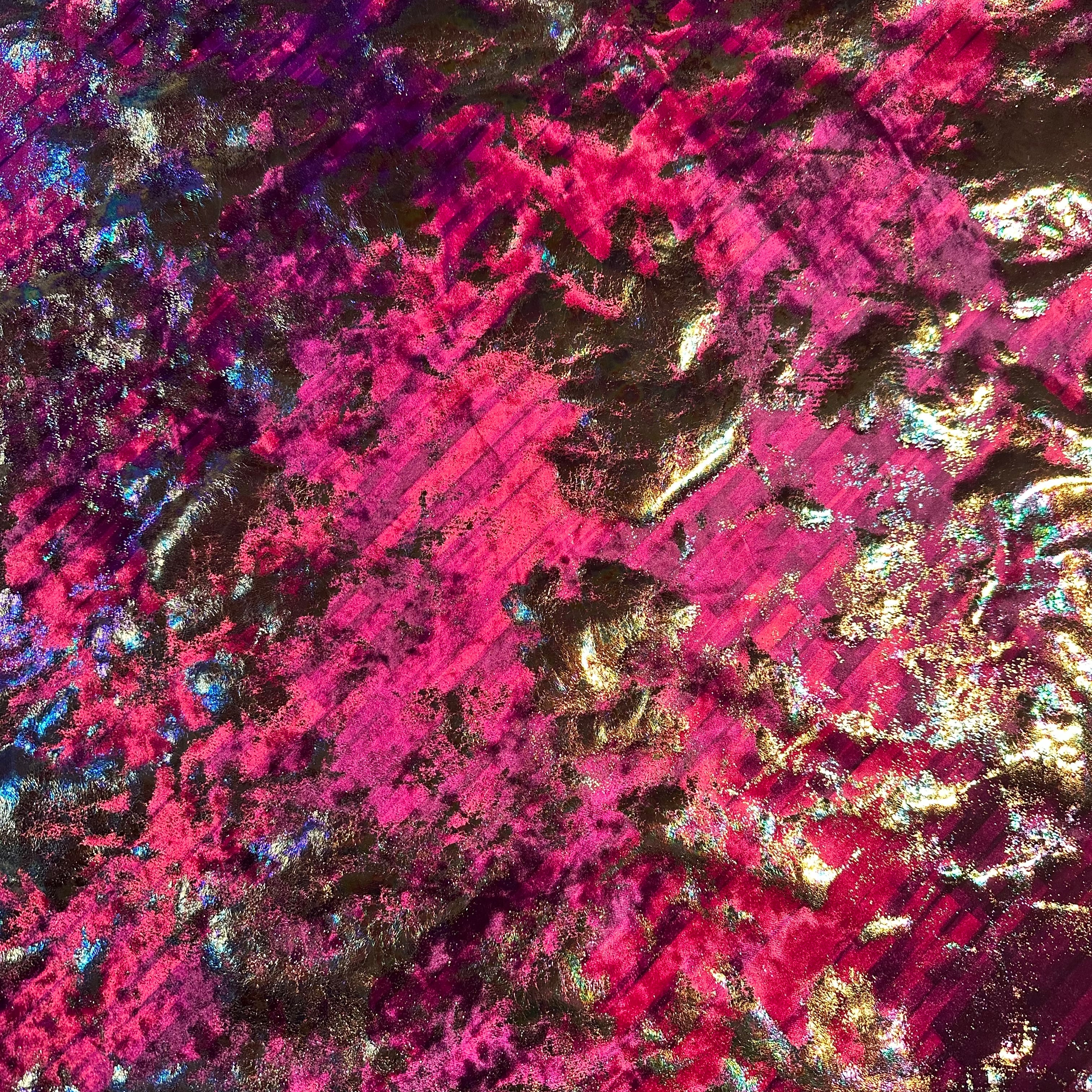

Special Considerations for Foil-Enhanced Tricot

- Protective Measures: Handle foil tricot with care to prevent marring the foil surface. Use a teflon presser foot or a walking foot to reduce friction and avoid damage.

- Heat Application: Avoid direct heat. If pressing is necessary, do so from the reverse side with a pressing cloth and minimal heat. This prevents foil degradation and preserves the finish.

- Washing and Maintenance: Advise clients to wash foil-enhanced garments inside out, using a gentle cycle with cold water. Air drying is preferable to maintain the foil’s brilliance.

Finishing Touches and Professional Tips

- Topstitching and Edging: Enhance seam strength and aesthetic appeal with precise topstitching. Use a narrow zigzag or coverstitch for visible hems and edges.

- Detailed Fitting: For custom-fit garments, consider using a dress form to pin and adjust fabric pieces before final stitching. This ensures perfect alignment and fit.

- Reinforcement Techniques: For high-stress areas, consider reinforcing seams with additional stitching or fabric patches to prolong garment life.

Mastering these advanced techniques will elevate your work with nylon spandex tricot, allowing you to create sophisticated, high-performance garments. At Spandex Palace, we pride ourselves on providing top-tier fabrics to match your expert craftsmanship. Dive into your next project with confidence, knowing you have the skills to transform nylon spandex tricot into wearable art.

Happy sewing from the experts at Spandex Palace! Your precision and creativity, paired with our premium fabrics, are the perfect combination for exceptional results.